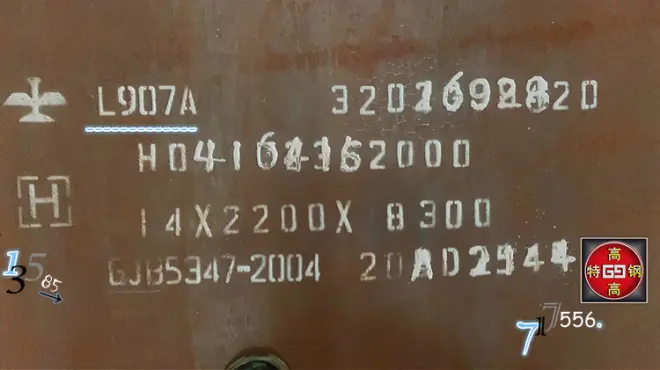

907A船板焊接

907A非耐压壳体用连铸钢板为特殊材料钢,机械性能好,强度高。因为 907A 材料的高强度可以更好地适应各种恶劣海况,焊接作为影响强度的重要环节,其质量显得尤为重要。

正确选用 与母材匹配的焊接材料是防止焊接缺陷的重要措施。母材为 907A 特殊钢材,所以使用焊条也选用907A 钢专用焊条TH907,符合 Q/725-1178-2001,规格有Φ4.0× 400 mm、 Φ3.2× 400 mm 两种。

Through the weldability analysis of 907A steel plate, TH907A welding rod was selected. After welding test, it wasused in the product after the welding test was verified to be qualified. Attention was paid to the selection of welding processparameters and the correct welding process, especially the treatment of welding rod before welding, and the control of parts and

weld temperature in the welding process, skillfully grasp the distance and angle between the workpiece and the electrode, strictlycontrol the welding quality, avoid welding defects, so that the welding performance of the product has achieved good results.

TH907A 手工电焊条属碱性超低氢型, 具有优良的塑性及韧性, 扩散氢含量低, 适用于直流电源反极性的全位置焊接。 焊条电弧稳定, 脱渣容易, 焊缝成型美观, 具有优良的抗裂性能。 可用于 907A 钢及相同强度级别低合金结构钢的焊接。